No professional bookbinding is complete or speaks higher quality than an immaculately perfected case binding. Spiel associates has been in the business of distributing bindery equipment to printers and fibre industries since 1963 and offers solutions to business in changing printed materials into high level polished books that have every chance of being around for many years to come.

Understanding Case Binding: The Gold Standard

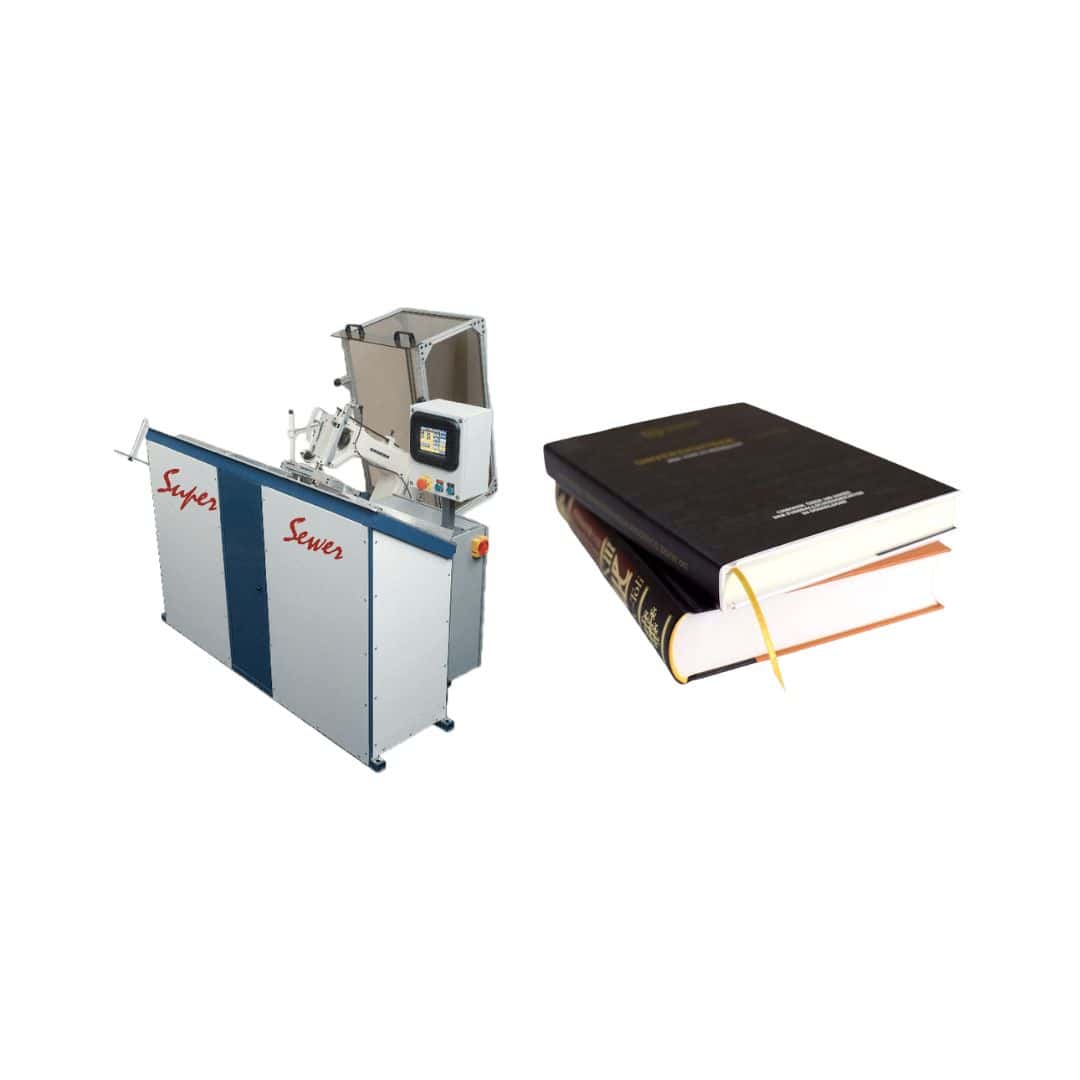

The classic process of producing hardcover books is called case binding, in which pages are sewn together into a book block and over which protective material is applied to pieces of book board. This method has been the option of choice in high literary works, corporate presentation, photo books and speciality publications.

The workflow starts with printed material that is cut, folded, ganged together and finished in what is know as smyth sewing into a book block. The difference in case binding is that it is durable and has a formal look. When compared to perfect binding or spiral binding, case binding produces products that will last and endure years although being treated with hands and still will have the beautiful look.

Why Invest in a Professional Case Binding Machine?

Considering purchasing a case binding machine is a smart step forward in the direction of quality and efficiency. Spiel Associates provides solutions by providing both small size production, bindings to large size production equipment to ensure that even small business can have professional outcomes.

Contemporary case binding equipment avoids the guesses and inconsistency of manual procedures. Machines such as the Casematic make wrapping corners easy and precise when blocking up boards and printed covers. Such accuracy can be directly related to customer satisfaction and waste.

The productivity increases are enormous. Compared to 10-12 books per hour that are made with hand-binding, professional binding machines can expand production rates by a huge factor, but still hold very high quality standards. Such scalability enables the business to accept bigger projects and work to shorter deadlines without any quality impairment.

The Case Binding Process: Craftsmanship Meets Technology

Case binding method is one whereby pages are sewn and bound in a rigid casing of hard cardboard covered on printed paper and covered with vinyl, cloth or leatherette. This is a multi-step procedure, which demands accuracy at each point.

Preparation of text blocks consists in aligning and sewing signatures. In this case endpapers are pasted down to keep the text block in position, but so as to be able to open it correctly. Modern case binding machines automate these very important processes, maintaining consistency with the added benefit of saving labor costs.

Choosing the Right Case Binding Equipment

The products offered by Spiel Associates include a broad selection of finishing machines (all the different types of case binding machines, stitchers, creasers, the UV coating machines, laminating machines, the paper punches that can go on a table top, and the spiral binding machine that are made of plastic material). This broad portfolio will make businesses get optimal solutions to their unique requirements and budget.

The most important considerations in the selection of a case binding machine are the volumes of productions, book sizes, and features needed. Automated systems help to speed and ensure consistency by offering high-volume systems. Semi-automatic equipment may meet the needs of smaller-scale operations, particularly because they are relatively affordable and still provide professional results.

Professional case binding equipment guarantees that all books are of the best quality when manufacturing a single custom book or several thousand books to be sold on the market.

The Spiel Associates Advantage

Spiel Associates works around production requirements of clients rather than re-engineering of production systems to satisfy equipment requirements. Binderies all over the country have trusted them since 1963 as their trusted partner in this customer-based approach.

Tons of different used binding machines in stock with used binding equipment the most common being reconditioned and warrantied. They also have this quality commitment which is reflected on their whole line product where customers are served with good quality equipment irrespective of price allowed.

Future-Proofing Your Operations

Spiel Associates operates in accordance with production needs of clients regardless of engaging in the re-engineering of production systems in order to meet equipment needs. Since 1963 they have been the trusted partner of binderies across the country in this customer-driven method.

Different used binding machines in stock, used binding equipment being most common reconditioned and warrantied. They also possess this quality commitment in the sense that the customers are supplied with good quality equipment at the expense of their entire line of products.

Conclusion

Case binding is still the crown jewel of book production quality and case binding machines are the professional tools that a serious business needs to produce the highest quality products. Of course with the pro tips, and large range of equipment available at Spiel Associates, consistent professional case binding is now more accessible than ever before.

This can be in terms of upgrading an existing equipment to entirely venturing into hardcover production from start to finish, the quality case binding machine can revolutionize business possibilities. The investment will generate returns in the form of enhanced efficiency, less waste and even the capacity to charge high prices in higher quality products.

Call Spiel Associates today at 877-BINDERY on how the most appropriate case binding machine can take your binding effort to the next level and find new horizons of flourishing and profitability.