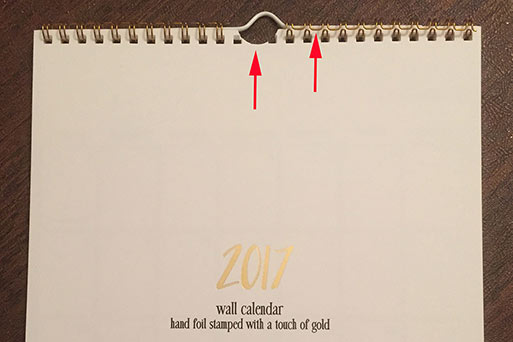

Bad Wire-O Binding

What’s wrong with this picture? My daughter recently purchased a calendar for her friend (meaning I purchased it) and showed it to me when she received it in the mail. My kids always make fun of me when I look at the binding of the book before opening it. Here there was something interesting.

This is punched with a “thumb cut” for calendars with hangers. This is more popular in Europe than it is here in The US. Most of our calendars have a round “hanger hole” at the opposite end of the binding edge. Parenthetically we sell the only paper punching machine that can punch the hanger hole simultaneously with the binding edge. We have sold The Sterling Punchmaster to many printers who for work for Shutterfly. Please see The Sterling Punchmaster video under New Equipment, Punching Equipment above.

Normally one would purchase a 3:1 square hole, wire die with a thumb cut but that means doubling up on dies. You would also need a normal 3:1 die to punch books without a thumb cut. An economical option is to punch a thumb cut calendar is to purchase a 3:1 wire die and a separate thumb cut die. But here is the rub: You need to open the 3:1 die and pull out the center 3 or 4 pins to make room for the thumb cut pattern.

Here the printer did one of two things wrong. Either they are using a die where the pins cannot be pulled or they just didn’t bother pulling them out. The latter is most likely because even economical, table top punches like The PDI Rhino punches use dies where the pins can be pulled. This would have prevented a book that doesn’t look so good. Also, it is industry practice for the closed wire to be between the last page of the book and the rear cover.

If you have any questions or comments, please feel free to post them.

By the way, my daughter’s friend still likes the calendar. I didn’t have the heart to point this out to her. I that hope she doesn’t read this blog.