Plastic Spiral Binding

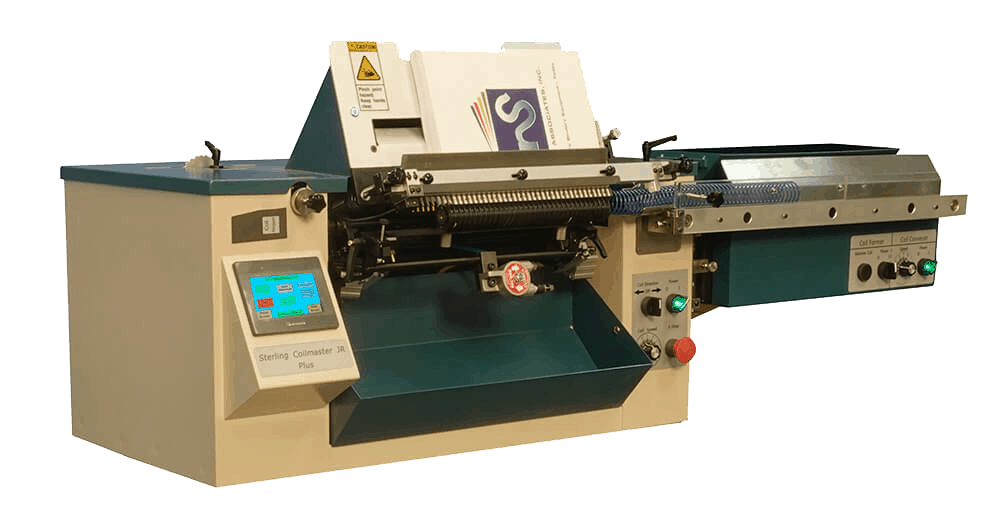

Coilmaster Jr. Plus

Product Gallery

Product Description

The STERLING® COILMASTER JR. PLUS is an automatic, table top plastic spiral binding machine. It inserts plastic spiral from the first hole onwards, then cuts and crimps automatically. This tabletop unit is affordable and can bind books from 8 mm to 30 mm. Speeds of up to 600 books per hour can be attained. The new in-feed conveyor allows for in-line binding with a coil former.

This plastic coil binder can bind books of any pitch, with round or oval holes. The margins can be slim or wide, up to 3/8” / 9.5 mm, meaning that you can pull punch pins prior to punching, and center the sheet. It can bind books of any length between 4” / 102 mm and 14” / 356 mm— not just a couple of standard sizes. The criss-cross combs guide the coil from both the front and the rear ensuring stable coil insertion. The crimping knives create a ninety degree crimp.

The STERLING COILMASTER® JR. PLUS offers quick and easy set up and minimal table top space. Why bind plastic spiral books by hand when you can bind them quickly and easily with… The STERLING COILMASTER JR. PLUS?

The Sterling® Coilmaker Plastic Coil Former

Making plastic coil just prior to insertion puts an end to working with twisted and deformed coil or coil with an improper pitch. Freshly made coil binds books more easily than coil taken out of a box. Cut the filament to the exact size you need, when you need it and cut down on waste, excess, and on storage. The cost of manufacturing coil is significantly less expensive than buying it preformed.

The STERLING® COILMAKER forms high quality plastic coil from plastic filament. This is achieved through the use of three axles pressing the filament against the forming mandrel as the coil is formed. Other coil formers only use two axles to press against the mandrel. This can cause “wobble” and produce coil that is not uniformly round, especially on larger sizes. This technology is why most of the plastic coil in America is made on this machine. The patented conveyor system ensures sufficient cooling time to make the most uniform coil available. The coil cools while it is still straight instead of laying twisted in a box. The heating element is infinitely variable to compensate for the ambient temperature at any given location. Tooling for sizes up to 50 mm is available for The COILMAKER.

Product Features

Testimonials

The Coilmaster Jr. is very easy to set up and reliable as can be. We train temps to run the machine and they do a great job. We save 60 – 70% on plastic coil costs by making our own coil.

Their training was awesome. Now the girls that were trained are training others. We are coil binding 18″ long books. The Coilmaster is truly great!!!

We had never done coil binding before we purchased The Sterling Digipunchmaster and The Coilmaster Jr. Plus. We bound 2,500 on our first day of production. Since we purchased them during the pandemic, we received no installation or training, just great installation and training videos.