Laminating

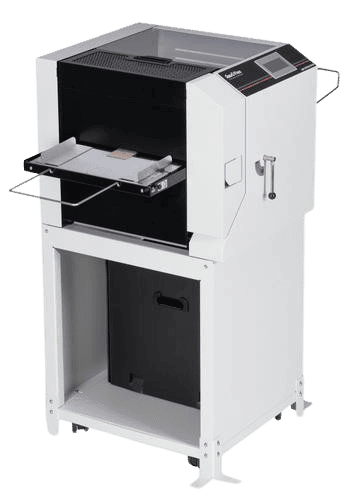

LAMI Revo Flex

Product Gallery

Product Description

The LAMI Revo Flex fully automatic laminator is the next generation of sheet-fed, auto-trimming lamination technology. With a push of a button, it’s easy to automatically feed, laminate and trim a stack of sheets with incredibly accuracy and consistency. The Flex boasts a maximum laminating speed of 78.8″ per minute and can process up to 420 sheets per hour with a 4-side trim function that can alternate between no margin (flush-cut) and margin (encapsulated).

The sheet feeder for the Flex holds up to 200 sheets at a time, with a minimum sheet size of 7.75″W x 6.75″L, a maximum sheet width of 13″ and a long-mode function that allows for infinite sheet length. The feeder will accept paper weights ranging from 16lb bond (60gsm) to 130lb Cover (350gsm), with built-in skew adjustment and adjustable resist roller pressure to prevent multi-sheet feeds over a wide range of paper stocks. All digital adjustments can be made using the easy-to-use touch screen panel, with temperature controls ranging from 176 – 284°F and a quick warm-up time of 5 minutes.

What really sets this machine apart is its revolutionary “No Waste” mode, which produces ZERO trim waste between encapsulated sheets. Even with sheets that are flush-cut, the unique engineering of the Revo Flex reduces trim waste by 70% compared to other automatic laminating systems. This significant reduction in trim waste translates to thousands of dollars saved in lamination costs over the lifetime of the Revo Flex. Lamination film rolls for the Revo Flex come in 12.6″ widths and are currently available in 1.5mil, 3mil and 5mil thicknesses in gloss and matte finishes.

Testimonials

The Coilmaster Jr. is very easy to set up and reliable as can be. We train temps to run the machine and they do a great job. We save 60 – 70% on plastic coil costs by making our own coil.

Their training was awesome. Now the girls that were trained are training others. We are coil binding 18″ long books. The Coilmaster is truly great!!!

I purchased my first Digibinder in 2007. I get buried once a year by Town Reports so I bought another one. Once a year I drive one of them down to Spiel for preventative maintenance. These things last forever.

The Wiremaster Pro is amazing. It does the work of three wire binders with half the labor. We love it.

We’ve been doing plastic coil binding for 30 years but David Spiel really took us back to school. He is the first vendor ever to teach us about pitch, and filament gauge, hole shape and diameters. The Coilmaster Jr. Plus rocks!

We had never done coil binding before we purchased The Sterling Digipunchmaster and The Coilmaster Jr. Plus. We bound 2,500 on our first day of production. Since we purchased them during the pandemic, we received no installation or training, just great installation and training videos.

I can’t say enough good about the people at this company. They are excellent to work with. I like the equipment they sell too.

I can’t say enough good about the people at this company. They are excellent to work with. I like the equipment they sell too.

What we like is the ease of operation and set up. The machine is what I call an open system, a machine where it is easy to see how it operates and easy to locate all the functions.

We’re getting 650 books per hour on The Coilmaster and we’re loving it. We have 250,000 books to do in the next two months and instead of dreading this job like we used to, we now say: Bring it on.

In-line coil forming and inserting is the most important feature for us on the Coilmaster. Buying and waiting for plastic coil proved to be a hardship. We can now optimize our production time, turning around multiple jobs more quickly.

We tried another automatic coil machine and it failed to perform. We bought a Coilmaster System and after it validated our decision, we bought two more systems. This machine gave us the production speeds we were looking for.