4 Tips for Making Notebooks and Journals

Sites like Pinterest and Etsy are inspiring a new generation of Do It Yourself-ers, and many crafters are turning their hobbies into a means of income.

Journaling and sketching are very therapeutic for a lot of people. And while the real treasure is the personal work inside, having a beautiful, high-quality notebook cover does your work justice. If you love to make your own notebooks, journals, diaries, scrapbooks, sketchbooks, or just plain books, then you can create gorgeous DIY journals using a wire binding machine.

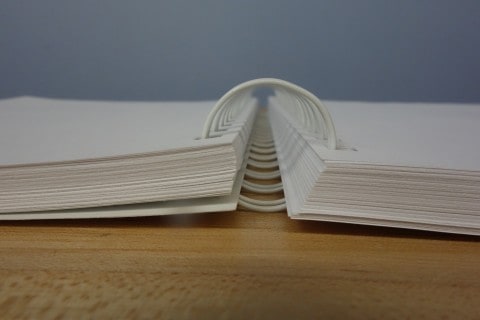

A wire binding machine is one of the best methods of binding a book, because the book lays flat without force, and the pages can be folded back onto themselves to keep other pages out of the way.

Here are some simple DIY steps to creating a professional looking book to sell or use on your own:

- First you need to know what kind of book you’re going to make. How large do you want the book to be? What kind of material will it hold? For journaling, simple printer or specialty paper will do, but for scrapbooking, you will want larger sized pieces of heavy paper or cardstock that can hold up to the photographs that will be put inside of it.

- What orientation do you want the pages to be? Portrait or landscape? Vertical or horizontal? Or are your pages perfectly square? You may want to change the orientation of your pages depending on the type of book you’re making. Wide, broad pages are more suitable for scrapbooks, but narrow, vertical pages can be great for small notebooks. You can also play with which side you want the book bindings to be on. Just be sure that your pages are set up well to accommodate an automatic paper punching machine. If there are designs on the pages, you may want to rethink how you want to set the bindings up.

- How many pages will the book be? For a blank book, it’s hard to make that decision. But as the bookmaker, you need to know what size coils to buy and which setting to put the coil binding machine on. If this isn’t taken into account, the binding either won’t fit or will be too heavy for the book, causing friction. Using punch tools with near-polished flanks and a quarter degree back taper reduces the friction, increasing the life of the punch tool as well as the paper it punches.

- After the heavy planning comes the more fun things. What kind of colors do you want on the book? Do you want an envelope pocket in the front or back to hold bookmarks, mementos, or other pieces of paper? As the creator, you can do whatever you want!

In order to craft the perfect custom notebooks, you’ll need a high-quality wire binding machine. Spiel Associates, Inc. has book binding equipment to accommodated DIY books of all sizes.