Many wonder what certain machinery dealers do to a used machine prior to selling it. Machines can be sold in the following conditions: “As Is”, “Good Running”, “Reconditioned”, and “Rebuilt.”

As Is

Is the way you buy a machine at an auction. If you ask a machinery dealer to guarantee that the machine cycles, he generally will. We certainly will.

Good Running

This means that the machine runs, it may have worn parts but the machine will operate as it should.

Reconditioned

Generally describes a machine that has been checked, worn parts replaced, cleaned, and if necessary, painted. This machine should run well and we warranty the machine.

Rebuilt

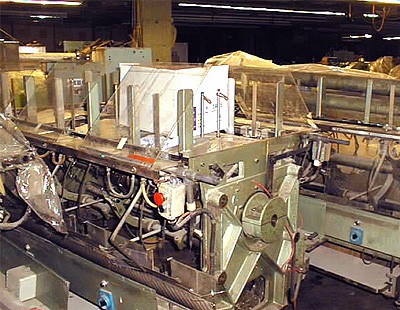

Is a little trickier. To some it may mean that every nut, bolt, bushing, and bearing is replaced with new ones. To others it may mean that all moving parts are replaced. Either way the machine should be stripped to its frame, assessed and literally re-built. This is how SPIEL ASSOCIATES rebuilds most of our used collators. We strip the machine down; replace all moving parts and tubing. We clean and paint the machine. Below please find a series of pictures representing a rebuild of a Sterling Collator.

This is how the machine looked when it came in

The machine is stripped down to its frame and painted.

All parts are assessed and/or repaired and replaced.

The gathering arms are assembled and the parts are installed.

The rest of the machine is assembled and new hoses are installed.

The machine is now ready for testing. It will be sold with a warranty on parts and labor.

Here are other reconditioned binding machines Spiel Associates has sold in the past.

Sickinger/GBC Automatic Punch

The Portland Punch

Nygren/Dahly Heavy Duty Drill

The Sterling Automatic Punch

Didde Gather-All Collater

When ordering used machinery through Spiel Associates or any other machinery dealer, make sure that you investigate what condition the machine will be sold: As is, good running, reconditioned, or rebuilt.