A few months ago I received a letter, not and e-mail, from an inventor who had designed a brochure with a flat spine. Enclosed was a brochure stapled to a 7/8 inch wide, 11 inch long piece of cover stock with printing on it. It was very unusual. I called the inventor, a Mr. Rodney Smith of Smith-Midland Corporation to see what it is that he wanted.

Rodney wanted us to invent a machine that would stitch these strips onto the spine of the brochures. He was not a printer but would purchase the machine for a printer who did work for him. I replied that this was a tremendous undertaking. How do you feed a 7/8 inch by 11 inch sheet to align with the spine of an sixteen page stitched booklet? It was also round cornered to boot.

I told Rodney that my father, Norton Spiel, would be calling him. My father, trained as an engineer loves solving bindery problems. In fact, I think he likes it more than selling machines. So here these two elderly gentlemen began talking.

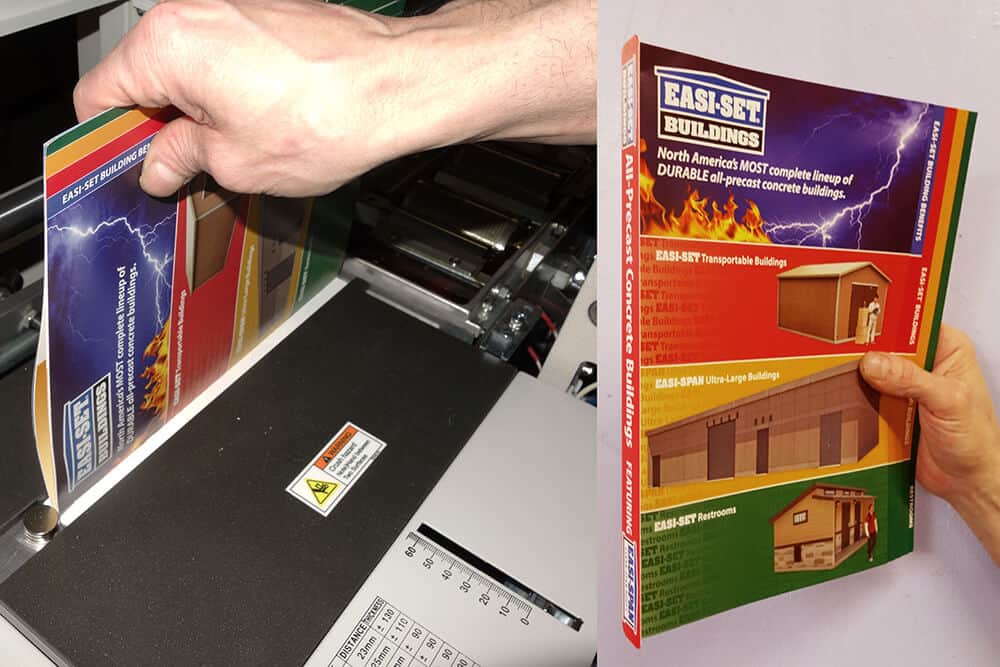

My father came up with the brilliant idea of perfect binding the booklet onto the one inch wide sheet of cover stock. Yes, some small modifications had to be made and no, it would not operate at the speed that Rodney had requested. Still it was a lot faster than having an operator staple, and I do mean staple, each booklet twice. The operator was getting 60 booklets per hour. The purchase of a Sterling Digibinder perfect binding machine would allow him to bind 250 books per hour.

Rodney and Chris Hottle of Winchester Printers in Winchester, VA came up for a demo and was impressed with the machine. We disabled the nipping table and created a stop so that the 7/8 inch strip could be placed uniformly every time. The machine worked like a charm.

The machine was ordered and is now in operation, binding booklets as planned. Sometimes it takes an old hand to come up with new ideas. Thanks Dad.